PUBLIC CONSULTATION

OUR VISION

“Enable our planet’s transition to sustainable energy”

OUR MISSION

“Increase the supply of low-carbon lithium chemicals”

Green Lithium will build one of Europe’s first large-scale lithium refineries at PD Ports in Teesside, UK. The creation of this substantial facility will begin to meet the urgent needs of the battery manufacturing and automotive sectors within the UK and the EU. Ultimately, without a localised supply of lithium chemicals, these sectors in Europe will fail.

OUR VALUES

Sustainable

Purpose led to leave our planet in a better place

One Team

Collaborative, transparent approach – including partners – showing trust, respect and care to optimise the value of our diversity to deliver together

Responsible

A culture of safety, quality and wellbeing, consistently doing what we say we are going to do

Agile

Leading the energy transition by being informed and responding to our environment

Excellent

Continuous improvement to deliver enhanced outcomes for our customers

OUR BUSINESS MODEL

PROJECT BENEFITS

- Substantial long-term investment within the Teesside area that will bring major new employment opportunities in the emerging green technology sector.

- The plant will have flexibility of feedstock to produce different battery-grade lithium chemicals and meet dynamic end-market needs.

- Highly sustainable process that will produce lithium products with the lowest possible environmental and carbon impact.

- Creating circular economies in battery recycling whilst eliminating process waste through sustainable re-use of co-products.

- Delivering the first-of-a-kind project with an execution-focused team with extensive experience completing multi-billion-pound, internationally strategic infrastructure programmes.

THE CHALLENGE

The global demand for electric vehicles (EVs) and battery technology is being driven by the need to decarbonise the world’s economy and to transition from fossil fuels.

Electrification is an unstoppable megatrend – governments, carmakers and consumers have committed to phasing out fossil fuels and transitioning to EVs and battery storage for our transportation and energy needs. Consensus is that global EV sales are set to double to over 20 million units by 2025.

A major component in EVs is the lithium-ion battery – this battery is the main driver of cost, range and performance. Large EV battery capacities, combined with rapid EV uptake has led to a surge in demand for batteries.

Lithium is a major ingredient for the most widely used batteries today, as well as next-generation ‘solid-state’ batteries. Demand for the lithium chemicals in batteries is growing faster than companies can bring on supply.

The primary feedstocks for lithium chemicals are found globally as lithium brine or hard-rock lithium ore. The latter, called spodumene concentrate, is the key feedstock for lithium hydroxide production.

But China dominates lithium refining. Shipping lithium hydroxide from China to Europe is unviable as the product can degrade over long shipping legs, while China’s own lithium requirement by 2030 outstrips its domestic production – it will no longer be an option for UK and EU supply chains.

THE SOLUTION

EUROPEAN REFINING CAPACITY

There is an essential need for localised production across the battery metals supply chain – the construction of the Green Lithium facility on Teesside will deliver a flexible lithium chemicals refinery that will fill a critical gap in the current UK and EU battery supply chain.

Teesside is a prime location in Europe for such a facility due to its industrial heritage, access to sea, rail and road, and strategic access to Net Zero Teesside – a globally significant carbon, capture and storage scheme.

OUR PROPOSAL

Green Lithium is proposing to develop and construct a low-carbon lithium refinery and associated dock-side reception, handling, storage and manufacturing facilities for the production of high-quality, battery-grade lithium. The development will initially see the construction of two production lines, with the potential for a further third line to be installed in the future. The proposed development area will include office and warehouse buildings, enclosed plant and structures that will cover approximately 37-45 acres (150,000-180,000m2) across a site of approximately 58 acres (250,000m2).

The process, based on two lines in operation, will import and process approximately 350,000 tonnes per annum of lithium mineral ore and will undertake an organo-alkali metal production process to manufacture approximately 50,000 tonnes per annum of lithium hydroxide.

KEY BENEFITS

SIGNIFICANT LOCAL, REGIONAL & UK ECONOMY BENEFITS

- Green lithium’s development will place the Tees Valley “on the map” for critical minerals and lithium battery materials, maintaining UK geopolitical relevance.

- Carmakers are set to launch 400+ new electric vehicle models – a lithium chemicals refinery at Teesside will strengthen the UK automotive industry and reduce our current reliance on Chinese lithium production.

- As well as encouraging other battery metals and EV projects to locate in this new regional value chain, the development will unlock local and UK circular economy opportunities with battery recycling and sale of the refinery’s co-products.

ENVIRONMENT

- The strategic and economic need for more local supply chains and increasing consumer and regulatory demands for carbon-efficient production are mutually reinforcing.

- Currently operating Chinese lithium refineries are environmentally degrading and large emitters of carbon dioxide (CO2), typically emitting 16.2kg CO2 for every kg of lithium chemicals produced.

- Green Lithium will create a supply of lithium which, under its decarbonised scenario, will see 3.3kg CO2 emissions per kg lithium – 75% lower emissions than equivalent Chinese refineries and, in doing so, reduce UK carbon dioxide emissions.

- Green Lithium will achieve this by adopting and incorporating the latest clean-energy technology e.g., hydrogen gas fuel, carbon capture, utilisation, and storage (CCUS) and waste-heat recycling. This approach helps to decarbonise the overall supply chain, not just the industry’s end products.

- The refining process will generate lithium chemicals and by-products, not harmful waste. The refining process is environmentally-friendly and, as well as producing lithium chemicals, will also produce inert co-products that can be used in other industries.

LOCAL EMPLOYMENT OPPORTUNITIES

- 1,000+ jobs will be created in the construction phase, during which millions of pounds will be invested into the North East of England.

- 250+ permanent, skilled jobs will be created to operate the refinery, ranging from technical, engineering and refining through to office roles. We recognise the importance of growing our own and plan to introduce apprenticeship and graduate schemes.

- Once operational, there is the potential for a further 650 additional jobs to be created locally in the supply chain, e.g. in support services, welfare, cleaning, outage management and maintenance services, further adding to the local employment opportunities.

SITE OVERVIEW

Green Lithium’s proposal is designed to have the lowest possible impact on the surrounding area, and the current proposal for the PD Ports Kinkerdale development reflects the following:

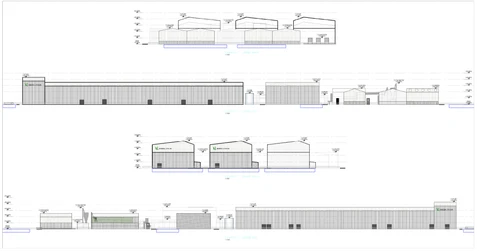

- The main process buildings will be purpose-built, insulated and noise-attenuated, double-skinned and fully-enclosed, resembling large modern Industrial buildings, approximately 380m long by 85m wide. Heights will vary depending on process area with maximum building heights in the range of 35m to 45metres. The buildings are “in keeping” with the surrounding developments and approved plans for the wider Teesworks development area. As such, the plant will not look out of place in Teesside.

- Large storage sheds for the primary raw material feedstock (lithium ore and minerals) and the co-product (analcime sand) will be built of a similar construction to the main process plant building and constructed to ensure the safe storage of our products and installed with all necessary pollution controls to prevent any releases of dust and noise.

- The calcination plant and associated equipment will be designed for external operation with noise-attenuation hoods fitted to key noise-generating components. The units have been designed to be able to operate using industrial hydrogen to enable Green Lithium to transition to a zero carbon combustion fuel source as soon as it becomes available at site.

- Green Lithium will also ensure that all combustion equipment is designed to be able to connect to the proposed CCUS equipment when it comes onstream in Teesside.

- Each of the calcination plants will have a chimney (approximately 40m high) that has been designed to ensure all emissions are suitably dispersed into the atmosphere without any impacts on local environment and surrounding habitats.

- All aspects of the plant will be regulated by the Environment Agency and installed with the “Best Available Techniques” with regards to pollution abatement and emissions control.

- Operational steam will be generated through a process of waste on site via a package boiler system feeding a common steam manifold. The boiler equipment will be housed in a purpose-built boiler house with integral stack some approximately 30m high.

- Each building roof area will be designed to support the installation of an appropriately designed photovoltaic (solar) scheme to provide renewable energy to the facility.

- Office and welfare facilities will be designed to use excess heat and energy generated from the wider plant and will be designed to have a net-zero carbon impact.

- The overall facility will be constructed to encourage the on-site use of EVs including vans, operational equipment and cars.

- The site will be enhanced visual using excavated materials for landscaping to provide an element of localised visual screening and to support environmental mitigation activities.

- The main office building will also be designed to accommodate a living roof and walls providing further environmental mitigation measures.

- 250+ permanent, skilled jobs will be created to operate the refinery, ranging from technical, engineering and refining through to office roles. We recognise the importance of growing our own and plan to introduce apprenticeship and graduate schemes.

- Once operational, there is the potential for a further 650 additional jobs to be created locally in the supply chain, e.g. in support services, welfare, cleaning, outage.

SITE LOCATION

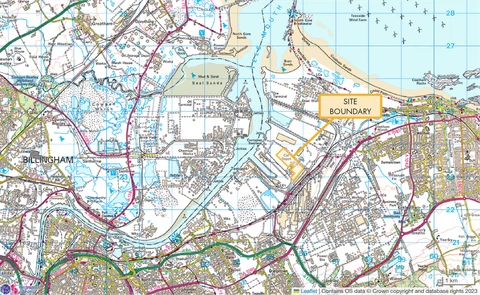

The proposed Green Lithium development site lies to the east of the PD Ports Teesport Bulk Cargo & Container Handling Port Facility, which is located on the south bank of the River Tees, as shown below. The site is located approximately 4.5km west of Redcar town centre and 5.5km to the north-east of Middlesbrough town centre.

The site is approximately 61 acres (250,000m2) in area, within the wider 779 acre (315,000m2) Teesport industrial, shipping and logistics estate in South Tees, and currently forms part of the wider port development area.

The site has a long and layered industrial history, with the site forming part of the Shell Teesside Oil Refinery until it was decommissioned and demolished in the late 1980s. Our project will help rejuvenate the site and turn it into a high value industrial manufacturing and employment centre.

The nearest residential area is an area of Redcar called Dormanstown which lies over 1.8km east of the site.

The River Tees is located approximately 800m to the north of the proposed development. The site is well defined by existing infrastructure corridors such as the Tees Valley Railway Line, which runs to the south of the Site. The site has good access to the A66 via the A1053 and Tees Dock Road.

BENEFITS OF THE SELECTED SITE

- Connectivity and market access: Excellent road, sea and rail links. PD Ports is the fifth largest port in the UK with one of the deepest general-purpose cargo quays in the UK. The port is capable of handling a variety of dry bulk and project cargoes making it an ideal location for supporting the import of the refinery feedstock material and exporting the finished product and associated by-products. It is an established gateway to global markets and a designated freeport.

- Integrated economic area: Teesport sits within the region’s energy hub, a business cluster that unlocks powerful collaborative potential between energy providers, world-class manufacturers and industry-leading suppliers. It is an integrated industrial area providing the opportunity for collaboration with the wider Teesside redevelopment initiative relating to offshore wind generation.

- Connection to the Teesside carbon capture scheme: The site is located in close proximity to the Net Zero Teesside CCUS project and will connect to it when it becomes available.

- Utilities availability: Existing infrastructure for connections to gas, electricity (including green energy) and future hydrogen supplies. Adjacent supply of industrial gases, such as oxygen and nitrogen, which are required for the Green Lithium process.

ENVIRONMENTAL IMPACT

Green Lithium is dedicated to creating an exemplary sustainable development, with consideration given to the environment at all stages of the development. To ensure the surrounding communities of Redcar and Middlesbrough and sensitive designated sites such as the Teesmouth Estuary are not negatively impacted by the development, expert consultants in their respective fields have been employed to assess the environmental impacts of both the construction and operational phases of the development.

Consultation with Redcar and Cleveland Borough Council was held at the start of the planning process, to determine which environmental areas could be impacted by the development. The point of this meeting was to agree upon the scope of the environmental impact assessment. If any of the environmental impacts were found by the expert consultants to exceed nationally set levels, mitigation measures would be required, or the development would not be approved.

The technical consultants of each area then assessed the baseline conditions of the site and surrounding area, including a review of both the condition of the site and the surrounding area, nominating relevant sensitive receptors. For example, ecologists were brought to the site in order to ascertain the current level of biodiversity and provide statements such as whether or not the area was likely to be suitable for bird nesting.

Thorough testing and modelling were completed after this, analysing the impact that the development would have on the specified receptors, with results presented and mitigation shown if required.

Each of these expert reports have shown that the Green Lithium development has a very low chance of impacting any of the receptors, and the advice given will be closely followed. Therefore, the conclusion from the assessments undertaken is that it is extremely unlikely that adverse impacts will be felt by any of the surrounding receptors to Green Lithium.

The ecology of the site is minimal, and any habitats lost will be either reintroduced on site, or offset off site through a not-for-profit scheme providing ecological enhancements to other sites within the Teesmouth Estuary.

Emissions released into the air have been modelled from the development and demonstrated that plumes are not likely to impact the Teesmouth Estuary or the residents of the local area. Transport is another area which Green Lithium has analysed, and found that the development once again will not negatively impact the Teesside site, local transport systems or the local community.

There have been no major issues found through the planning of this development, and any minor issues have been fixed and amended accordingly, with plant design and equipment selection being changed to limit the impact on receptors to a minimal level.

In addition, national and local legislation has been followed closely in all parts of this application, with each of the technical areas demonstrating the development will indeed be below the limits set out.

The planning application for the development will be accompanied with a comprehensive Environmental Impact Assessment (EIA) that provides a rigorous assessment on all aspects of the process and its effects on the environment, including:

- Air quality

- Sensitive habitats and ecology

- Noise and vibration

- Visual impact

- Odour, dust and pollution

- Transport

- Cultural heritage

- Waste generation impacts

- Carbon and greenhouse gases

The conclusions of the EIA have been presented over 3 volumes and will be available for download from the Green Lithium website.

THE PROCESS

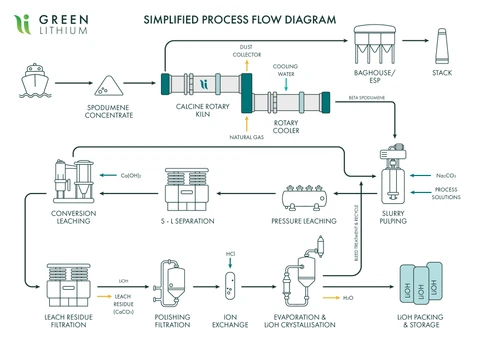

The Process can be broken down broadly into three key stages:

- Calcination

- Hydrometallurgy

- Crystallisation

CALCINATION:

The Calcination process breaks down the raw materials (also known as spodumene concentrate) by heating the material using natural gases within a large calcine rotary kiln, reaching extreme temperatures in excess of 1000°C. Once the material passes through the rotary kiln, it then passes into a rotary cooler to help reduce temperatures faster, allowing for safe handling of the material as it is prepared for the next stage.

HYDROMETALLURAGY:

The Hydrometallurgy process starts with grinding and pulping process, where calcinated material is wet ground and pulped into a slurry using recovered process water. This slurry is then passed into the autoclave unit where the alkali-leaching process (pressure leaching) takes place, using high pressure, high temperature steam and air. The resultant post leach slurry (comprising a lithium carbonate and analcime solid solution) is then transferred to the S-L separation/filtration unit where the material is washed and dried. The dried material or leach residue filter cake, is then transferred to a two stage Lithium Hydroxide conversion leaching process, where the cake is further broken down, repulped with recycled wash filtrates, mixed with calcium hydroxide and then passed through conversion reactor tanks. A further filtration process separates solids and liquids, with the resultant liquids being feed to the second stage conversion process. The second stage conversion removes unwanted impurities that may contaminate the final product. Filtrate from both stages of the conversion process is then filtered, polished and cleaned before being passed to the Ion Exchange units where any remaining impurities are removed from the solution prior to the crystallisation stage.

CRYSTALLISATION:

A two stage Crystallisation Process will be provided to ensure product quality. The dilute lithium hydroxide liquor received from the Hydrometallurgy is essentially heated to evaporate the liquids producing crude lithium hydroxide crystals that are then further filtrated and dried to ensure all impurities are removed.

The output of this stage is then forwarded to the product storage and packing area for distribution to the supply chain.

The design output of the plant is to produce 50,000 tons per annum of battery-grade lithium hydroxide, based on using only 2 process lines, the 3rd line would potentially be installed at a later stage once the plant is in a steady state of operations.

Throughout the process above, the plant re-uses excess liquids and heat by re-introducing them at various stages to ensure we not only reduce our waste but also our carbon footprint.

TIMELINE

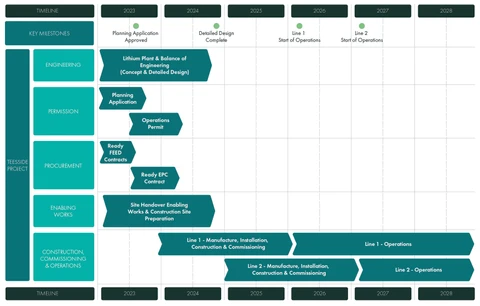

The Green Lithium project is planned to be operational from 2026.

The construction of the project will take place over a 2 1/2 year period, commencing in 2024 once all necessary planning approvals, construction contracts and enabling works have been completed.

Public Consultation Has Now Closed

Green Lithium Refining Limited (“Green Lithium”)

Thank you for taking the time to view our online public consultation exhibition, the review period has now ended. If you missed the consultation and have feedback, please contact us at the email or address below.

Green Lithium Refining Limited, Teesside University, Victoria Building, Victoria Road, Middlesbrough, TS1 3BA

publicconsultation@greenlithium.co.uk

All responses will be treated confidentially and some of the comments provided may be submitted as part of the planning application.